Understanding MMA Welding Machines and Stainless Steel

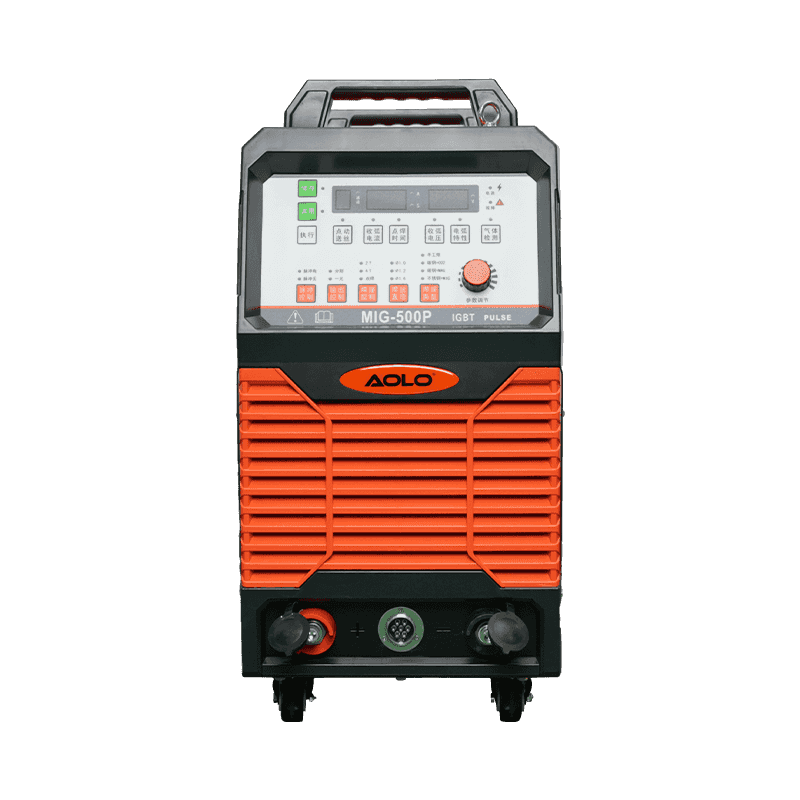

An MMA Welding Machine, also known as a manual metal arc or stick welding machine, is widely used for its simplicity, portability, and adaptability to different working environments. When it comes to stainless steel, many users wonder whether MMA welding is a suitable option. The short answer is yes, an MMA welding machine can weld stainless steel, but the quality of the results depends heavily on electrode selection, machine settings, and operator skill.

Stainless steel has distinct properties compared to carbon steel, including higher chromium content and greater sensitivity to heat. These characteristics affect how the metal melts, cools, and reacts during welding. Understanding how MMA welding interacts with stainless steel is essential before deciding whether this method meets your project requirements.

Why Stainless Steel Can Be Welded with MMA Welding Machines

MMA welding works by creating an electric arc between a flux-coated electrode and the workpiece. This process is fundamentally compatible with stainless steel because the arc provides sufficient heat to melt both the base metal and the electrode. The flux coating also offers protection against atmospheric contamination, which is particularly important for stainless steel.

Another advantage is versatility. MMA welding machines can operate on AC or DC power and can be used in outdoor or less controlled environments. This makes them practical for stainless steel repairs, construction work, and maintenance tasks where more delicate welding methods may not be feasible.

Choosing the Right Electrodes for Stainless Steel Welding

Electrode selection is one of the most critical factors when welding stainless steel with an MMA welding machine. Stainless steel electrodes are specifically formulated to match or complement the alloy composition of the base metal. Using the wrong electrode can result in weak welds, cracking, or corrosion issues.

Common Stainless Steel Electrodes

- E308 or E308L for welding 304 stainless steel

- E316 or E316L for welding 316 stainless steel

- E309 electrodes for joining stainless steel to carbon steel

Low-carbon versions (marked with “L”) are often preferred because they reduce the risk of carbide precipitation, which can weaken corrosion resistance after welding.

Machine Settings and Welding Parameters

Correct machine settings play a significant role in achieving clean and durable stainless steel welds. Compared to mild steel, stainless steel generally requires slightly lower heat input to prevent overheating and distortion. Excessive heat can lead to warping, discoloration, and reduced corrosion resistance.

Most stainless steel electrodes are designed for DC positive (DCEP) polarity. This setup provides a stable arc and better penetration control. Current settings should follow the electrode manufacturer’s recommendations, taking into account electrode diameter and material thickness.

Weld Quality Considerations for Stainless Steel

While MMA welding machines can weld stainless steel effectively, the resulting weld appearance may be less smooth compared to TIG welding. Slag removal is required after each pass, and spatter levels are typically higher. However, with proper technique, structurally sound and corrosion-resistant welds are achievable.

Maintaining cleanliness is crucial. Stainless steel surfaces should be free from oil, grease, and carbon steel contamination. Using dedicated stainless steel brushes and tools helps preserve the metal’s corrosion-resistant properties.

Comparing MMA Welding with Other Methods for Stainless Steel

Understanding how MMA welding compares to other welding processes can help determine when it is the right choice for stainless steel applications.

| Welding Method |

Precision |

Ease of Use |

Portability |

| MMA Welding |

Moderate |

High |

High |

| TIG Welding |

Very High |

Low |

Low |

| MIG Welding |

High |

Moderate |

Moderate |

Advantages of Using MMA Welding for Stainless Steel

One of the main advantages of using an MMA welding machine for stainless steel is flexibility. The equipment is relatively inexpensive, easy to transport, and suitable for on-site work. It is also tolerant of less-than-ideal environmental conditions, such as wind or uneven surfaces.

- Works well for repairs and maintenance

- Suitable for thick stainless steel sections

- Lower equipment cost compared to TIG systems

Limitations and Challenges to Be Aware Of

Despite its versatility, MMA welding is not ideal for all stainless steel projects. Thin materials can be difficult to weld without burn-through, and achieving a highly polished or aesthetic finish is challenging. Additionally, the need for slag removal increases labor time.

For applications requiring precise control, minimal heat input, or visually flawless welds, alternative methods such as TIG welding may be more appropriate.

Practical Tips for Welding Stainless Steel with MMA Machines

To improve results when welding stainless steel with an MMA welding machine, focus on preparation and technique. Keep the arc length short, move steadily, and avoid excessive weaving. Allow the weld to cool gradually to reduce thermal stress.

- Use stainless steel-specific electrodes

- Clean the base metal thoroughly

- Control heat input carefully

Conclusion: Is MMA Welding Suitable for Stainless Steel?

An MMA welding machine can indeed weld stainless steel effectively when used correctly. By selecting appropriate electrodes, adjusting machine settings, and applying proper welding techniques, strong and reliable welds are achievable. While it may not replace TIG welding for high-precision or aesthetic applications, MMA welding remains a practical and cost-effective solution for many stainless steel projects.

English

English 中文简体

中文简体 Español

Español русский

русский

Contact Us